More Services

Explore Other Services

More Services

Explore Other Services

More Services

Explore Other Services

Questions? Contact us

Questions? Contact us

PHONE

416 877 7861

VISIT US

Vaughan, Ontario

info@jpresin.ca

Questions? Contact us

PHONE

416 877 7861

VISIT US

Vaughan, Ontario

info@jpresin.ca

Benefits:

✅ Durability and Longevity:

Metallic epoxy floors are highly durable and can withstand heavy foot traffic, making them ideal for both residential and commercial spaces.

When properly installed and maintained, metallic epoxy floors can last many years without significant wear and tear, providing excellent value over time.

✅ Aesthetics and Customization:

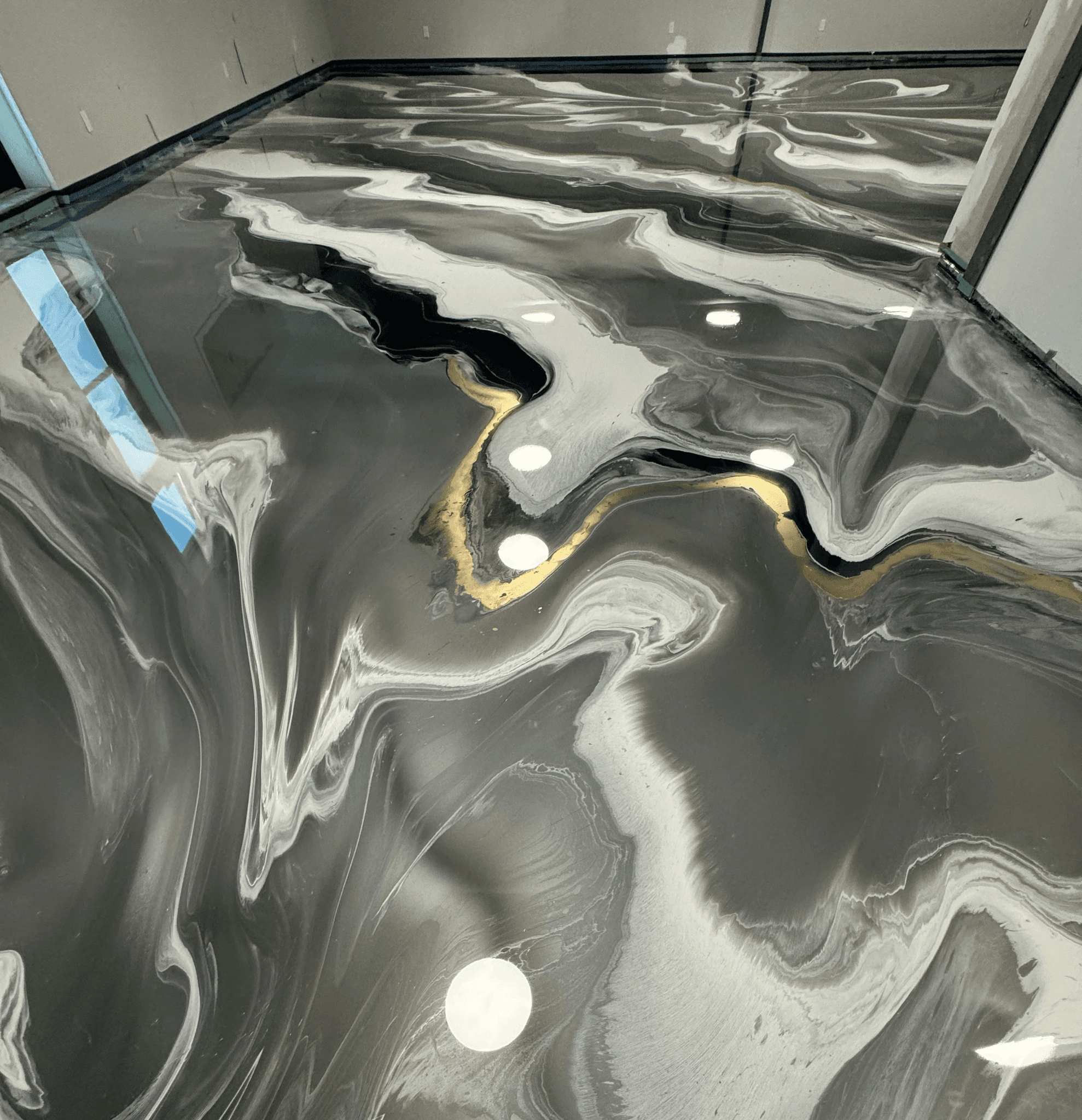

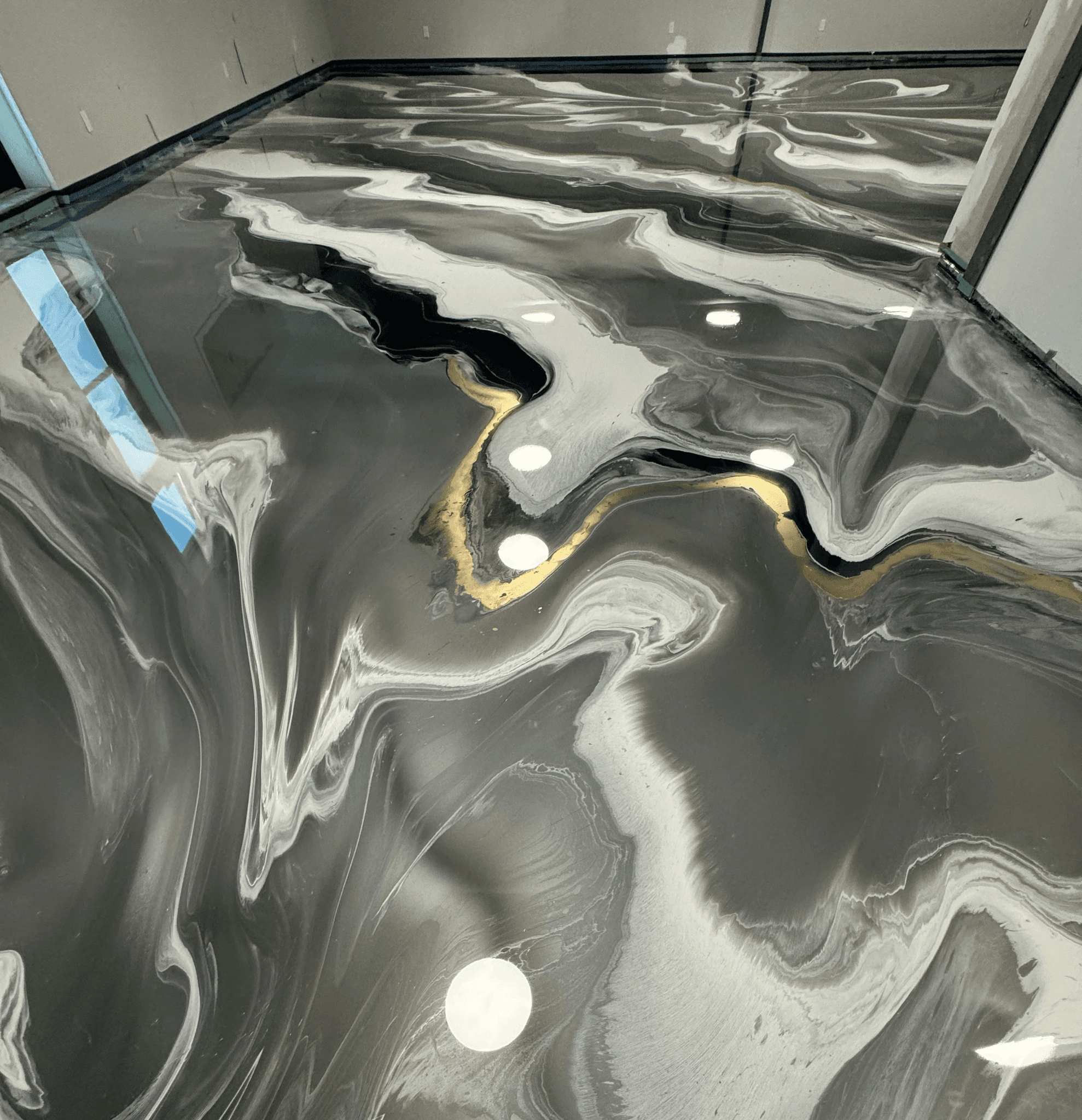

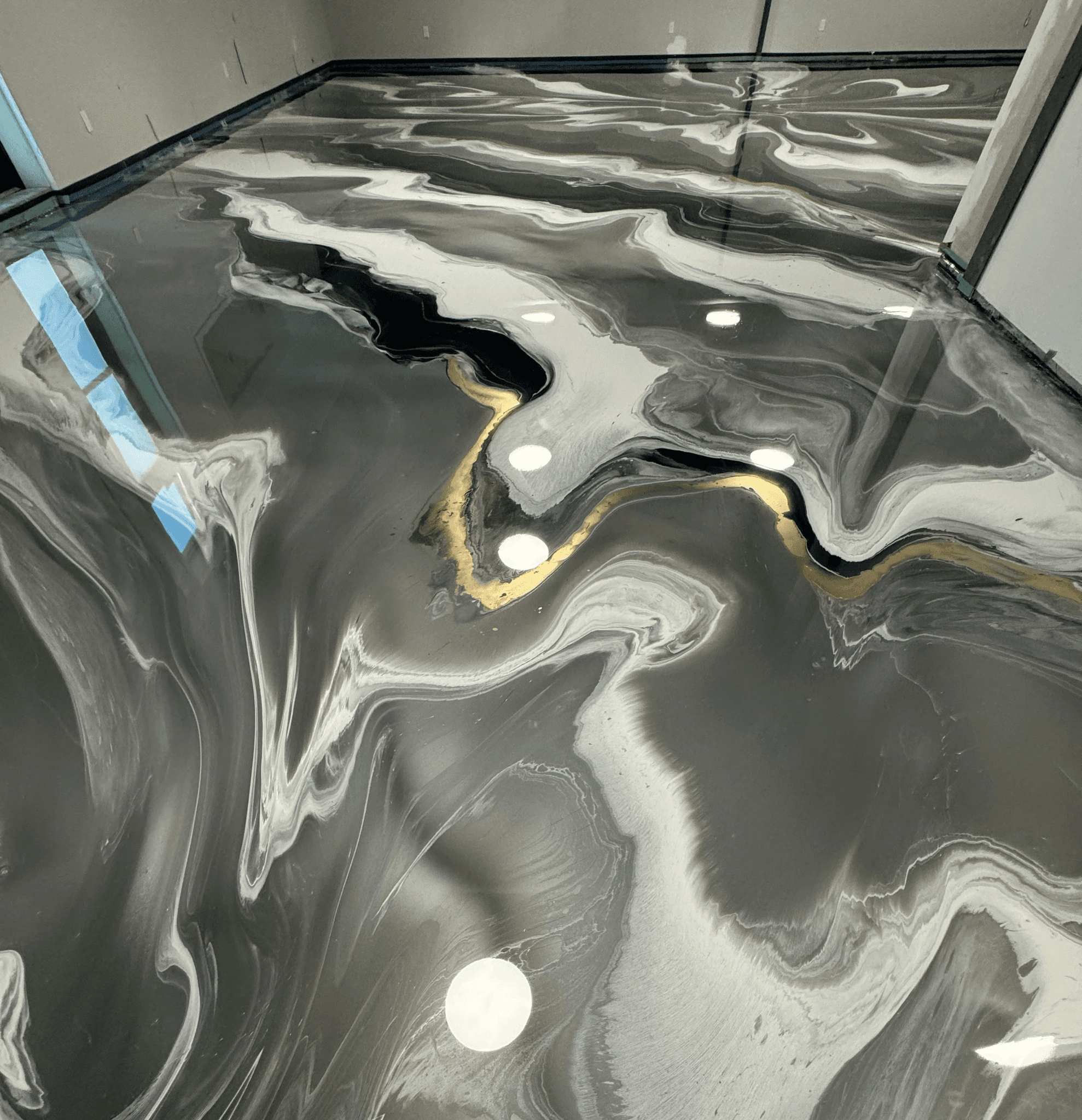

Metallic epoxy floors are visually stunning, offering a unique, high-gloss finish with a three-dimensional, marbled appearance. The reflective, pearlescent effects can create a sense of depth and movement.

✅ Maintenance & Hygiene:

These floors are easy to clean and maintain. Their seamless surface resists dirt and stains, requiring only regular sweeping and occasional mopping.

✅ Chemical Resistance:

Metallic epoxy floors are resistant to chemicals, oils, and other substances, making them suitable for garages, workshops, and industrial environments.

✅ Customizable:

With a wide range of colors and effects available, metallic epoxy floors can be customized to fit any design preference, from subtle elegance to bold, dramatic looks.

✅ Slip Resistance:

Additives can be incorporated into the epoxy to enhance traction and reduce the risk of slips and falls, making the floors safer for various applications.

✅ Hygienic:

The seamless nature of epoxy floors prevents the buildup of dirt and bacteria, contributing to a cleaner and more hygienic environment.

Application Proccess:

Surface Preparation:

The existing floor surface is thoroughly cleaned and prepped. This may involve grinding or shot blasting to remove any old coatings, dirt, oil, or contaminants and to create a profile for the epoxy to adhere to.|

Priming:

A primer coat is applied to ensure proper adhesion of the epoxy to the substrate. This also helps to seal the surface and reduce the risk of bubbles forming in the final coating.

Base Coat Application:

A base coat of epoxy is applied. This coat can be pigmented to create the desired background color for the metallic effects.

Metallic Pigment Application:

The metallic pigments are mixed into a clear epoxy and applied over the base coat. Various techniques, such as troweling, rolling, or spraying, can be used to create different effects and patterns. The pigments naturally settle and flow, creating unique, marbled, and pearlescent effects.

Manipulation:

While the metallic epoxy is still wet, it can be further manipulated with tools to enhance the desired pattern and effect.

Curing:

The floor is left to cure, which typically takes 24 to 48 hours, depending on the specific epoxy product and environmental conditions.

Top coat Application:

Once the metallic epoxy has cured, a clear topcoat is applied to protect the surface and enhance its durability, gloss, and chemical resistance.|

Final Inspection:

After the topcoat has cured, the floor is inspected to ensure a flawless finish. Any necessary touch-ups are made to achieve the desired look and quality.

Final Inspection and Clean-Up

A thorough inspection is conducted to ensure the floor meets our high standards of quality and appearance.

The work area is cleaned, and any protective coverings are removed.

Post-Installation Care and Maintenance Instructions:

• We provide you with detailed instructions on how to care for and maintain your new epoxy floor to keep it looking its best.

• Guidelines on how long to wait before using the floor to ensure it is fully cured and ready for foot traffic or furniture placement.

Scroll down to see some our completed projects

Benefits:

✅ Durability and Longevity:

Metallic epoxy floors are highly durable and can withstand heavy foot traffic, making them ideal for both residential and commercial spaces.

When properly installed and maintained, metallic epoxy floors can last many years without significant wear and tear, providing excellent value over time.

✅ Aesthetics and Customization:

Metallic epoxy floors are visually stunning, offering a unique, high-gloss finish with a three-dimensional, marbled appearance. The reflective, pearlescent effects can create a sense of depth and movement.

✅ Maintenance & Hygiene:

These floors are easy to clean and maintain. Their seamless surface resists dirt and stains, requiring only regular sweeping and occasional mopping.

✅ Chemical Resistance:

Metallic epoxy floors are resistant to chemicals, oils, and other substances, making them suitable for garages, workshops, and industrial environments.

✅ Customizable:

With a wide range of colors and effects available, metallic epoxy floors can be customized to fit any design preference, from subtle elegance to bold, dramatic looks.

✅ Slip Resistance:

Additives can be incorporated into the epoxy to enhance traction and reduce the risk of slips and falls, making the floors safer for various applications.

✅ Hygienic:

The seamless nature of epoxy floors prevents the buildup of dirt and bacteria, contributing to a cleaner and more hygienic environment.

Application Proccess:

Surface Preparation:

The existing floor surface is thoroughly cleaned and prepped. This may involve grinding or shot blasting to remove any old coatings, dirt, oil, or contaminants and to create a profile for the epoxy to adhere to.|

Priming:

A primer coat is applied to ensure proper adhesion of the epoxy to the substrate. This also helps to seal the surface and reduce the risk of bubbles forming in the final coating.

Base Coat Application:

A base coat of epoxy is applied. This coat can be pigmented to create the desired background color for the metallic effects.

Metallic Pigment Application:

The metallic pigments are mixed into a clear epoxy and applied over the base coat. Various techniques, such as troweling, rolling, or spraying, can be used to create different effects and patterns. The pigments naturally settle and flow, creating unique, marbled, and pearlescent effects.

Manipulation:

While the metallic epoxy is still wet, it can be further manipulated with tools to enhance the desired pattern and effect.

Curing:

The floor is left to cure, which typically takes 24 to 48 hours, depending on the specific epoxy product and environmental conditions.

Top coat Application:

Once the metallic epoxy has cured, a clear topcoat is applied to protect the surface and enhance its durability, gloss, and chemical resistance.|

Final Inspection:

After the topcoat has cured, the floor is inspected to ensure a flawless finish. Any necessary touch-ups are made to achieve the desired look and quality.

Final Inspection and Clean-Up

A thorough inspection is conducted to ensure the floor meets our high standards of quality and appearance.

The work area is cleaned, and any protective coverings are removed.

Post-Installation Care and Maintenance Instructions:

• We provide you with detailed instructions on how to care for and maintain your new epoxy floor to keep it looking its best.

• Guidelines on how long to wait before using the floor to ensure it is fully cured and ready for foot traffic or furniture placement.

Scroll down to see some our completed projects

Benefits:

✅ Durability and Longevity:

Metallic epoxy floors are highly durable and can withstand heavy foot traffic, making them ideal for both residential and commercial spaces.

When properly installed and maintained, metallic epoxy floors can last many years without significant wear and tear, providing excellent value over time.

✅ Aesthetics and Customization:

Metallic epoxy floors are visually stunning, offering a unique, high-gloss finish with a three-dimensional, marbled appearance. The reflective, pearlescent effects can create a sense of depth and movement.

✅ Maintenance & Hygiene:

These floors are easy to clean and maintain. Their seamless surface resists dirt and stains, requiring only regular sweeping and occasional mopping.

✅ Chemical Resistance:

Metallic epoxy floors are resistant to chemicals, oils, and other substances, making them suitable for garages, workshops, and industrial environments.

✅ Customizable:

With a wide range of colors and effects available, metallic epoxy floors can be customized to fit any design preference, from subtle elegance to bold, dramatic looks.

✅ Slip Resistance:

Additives can be incorporated into the epoxy to enhance traction and reduce the risk of slips and falls, making the floors safer for various applications.

✅ Hygienic:

The seamless nature of epoxy floors prevents the buildup of dirt and bacteria, contributing to a cleaner and more hygienic environment.

Application Proccess:

Surface Preparation:

The existing floor surface is thoroughly cleaned and prepped. This may involve grinding or shot blasting to remove any old coatings, dirt, oil, or contaminants and to create a profile for the epoxy to adhere to.|

Priming:

A primer coat is applied to ensure proper adhesion of the epoxy to the substrate. This also helps to seal the surface and reduce the risk of bubbles forming in the final coating.

Base Coat Application:

A base coat of epoxy is applied. This coat can be pigmented to create the desired background color for the metallic effects.

Metallic Pigment Application:

The metallic pigments are mixed into a clear epoxy and applied over the base coat. Various techniques, such as troweling, rolling, or spraying, can be used to create different effects and patterns. The pigments naturally settle and flow, creating unique, marbled, and pearlescent effects.

Manipulation:

While the metallic epoxy is still wet, it can be further manipulated with tools to enhance the desired pattern and effect.

Curing:

The floor is left to cure, which typically takes 24 to 48 hours, depending on the specific epoxy product and environmental conditions.

Top coat Application:

Once the metallic epoxy has cured, a clear topcoat is applied to protect the surface and enhance its durability, gloss, and chemical resistance.|

Final Inspection:

After the topcoat has cured, the floor is inspected to ensure a flawless finish. Any necessary touch-ups are made to achieve the desired look and quality.

Final Inspection and Clean-Up

A thorough inspection is conducted to ensure the floor meets our high standards of quality and appearance.

The work area is cleaned, and any protective coverings are removed.

Post-Installation Care and Maintenance Instructions:

• We provide you with detailed instructions on how to care for and maintain your new epoxy floor to keep it looking its best.

• Guidelines on how long to wait before using the floor to ensure it is fully cured and ready for foot traffic or furniture placement.

Scroll down to see some our completed projects

Photo Gallery

Our Gallery

Discover our past projects.

Photo Gallery

Our Gallery

Discover our past projects.

Photo Gallery

Our Gallery

Discover our past projects.

Frequently Asked Questions

Your Questions Answered!

Discover more about our services and policies with our Frequently Asked Questions section.

Frequently Asked Questions

Your Questions Answered!

Discover more about our services and policies with our Frequently Asked Questions section.

Frequently Asked Questions

Your Questions Answered!

Discover more about our services and policies with our Frequently Asked Questions section.

Question

Answer

What is the total cost estimate and what does it include?

Question

Answer

What are your payment terms?

Question

Answer

Does epoxy crack in the winter?

Question

Answer

How long does an epoxy job take?

Question

Answer

Is Just Perfect Resin liscensed and insured?

Question

Answer

Do you offer any warranties or guarantees on your work?

Question

Answer

Does epoxy resist against stains?

Question

Answer

What can epoxy be applied too?

Question

Answer

What is the total cost estimate and what does it include?

Question

Answer

What are your payment terms?

Question

Answer

Does epoxy crack in the winter?

Question

Answer

How long does an epoxy job take?

Question

Answer

Is Just Perfect Resin liscensed and insured?

Question

Answer

Do you offer any warranties or guarantees on your work?

Question

Answer

Does epoxy resist against stains?

Question

Answer

What can epoxy be applied too?

What is the total cost estimate and what does it include?

What are your payment terms?

Does epoxy crack in the winter?

How long does an epoxy job take?

Is Just Perfect Resin liscensed and insured?

Do you offer any warranties or guarantees on your work?

Question

Answer

Does epoxy resist against stains?

Question

Answer