More Services

Explore Other Services

More Services

Explore Other Services

Questions? Contact us

Questions? Contact us

PHONE

416 877 7861

VISIT US

Vaughan, Ontario

info@jpresin.ca

Questions? Contact us

PHONE

416 877 7861

VISIT US

Vaughan, Ontario

info@jpresin.ca

Benefits:

✅ Durability and Longevity:

Epoxy floors are known for their toughness and resistance to wear and tear. They can withstand heavy foot traffic, making them ideal for a basement that may be used frequently.

Epoxy flooring is highly resistant to impacts and abrasions, ensuring it remains intact and looking good even if heavy items are dropped.

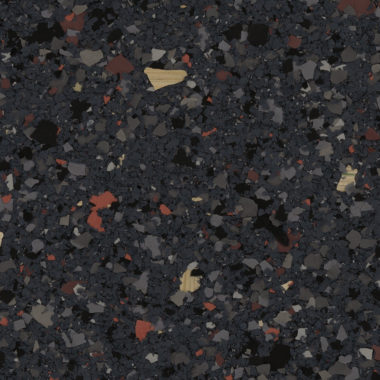

✅ Aesthetics and Customization:

A solid color epoxy floor provides a sleek, seamless, and contemporary finish that can enhance the overall appearance of the basement.

Available in a wide range of colors, you can choose a hue that matches your personal style or complements the existing decor of your home.

✅ Maintenance & Hygiene:

The smooth, non-porous surface of an epoxy floor makes it incredibly easy to clean. Spills can be wiped away effortlessly, and regular maintenance requires minimal effort.

Epoxy floors resist stains from liquids such as water, oil, and chemicals, ensuring the floor maintains its pristine look.

✅ Performance and Safety:

Epoxy flooring creates a moisture-resistant barrier, which is especially beneficial in basements prone to dampness or minor flooding.

Epoxy coatings can be customized with slip-resistant additives to enhance safety, reducing the risk of slips and falls.

✅ Installation and Usability:

Epoxy flooring can be installed relatively quickly, minimizing disruption to your home.

The seamless nature of epoxy flooring eliminates cracks and crevices where dirt and bacteria can accumulate, promoting a cleaner environment.

✅ Cost-Effectiveness:

Although the initial cost may be higher than some other flooring options, the durability and low maintenance requirements of epoxy floors can lead to long-term cost savings.

The improved appearance and functionality of a basement with epoxy flooring can increase the overall value of your home.

✅ Environmental Benefits:

Some epoxy products are low in volatile organic compounds (VOCs), contributing to better indoor air quality and a healthier living environment.

Application Process:

Initial Consultation and Assessment

Site Visit: We begin with a visit to your basement to assess the condition of the floor and discuss your colour and design preferences.

Preparation Plan: We’ll develop a tailored preparation and installation plan based on the specific requirements of your space.

Surface Preparation

Cleaning: The existing floor is thoroughly cleaned to remove any dirt, grease, or debris. This ensures optimal adhesion of the epoxy.

Repairs: Any cracks, holes, or imperfections in the concrete are repaired using an appropriate filler or patching material.

Grinding/Shot Blasting: The surface is mechanically ground or shot blasted to create a rough texture, promoting better bonding of the epoxy coating.

Vacuuming: The floor is vacuumed to remove dust and particles generated during grinding or shot blasting.

Primer Application

Primer Coat: A primer coat of epoxy is applied to the prepared surface. This penetrates the concrete, creating a strong foundation for the subsequent layers.

Curing Time: The primer is allowed to cure for the recommended period, ensuring it bonds effectively to the substrate.

Base Coat Application

Mixing the Epoxy: The epoxy resin and hardener are mixed according to the manufacturer’s specifications to achieve the desired consistency.

Applying the Base Coat: The mixed epoxy is applied evenly across the floor using rollers or squeegees. This base coat serves as the primary color layer.

Curing Time: The base coat is left to cure, typically overnight, depending on the product and environmental conditions.

Inspection and Touch-Ups

Quality Check: Once the base coat is cured, we inspect the floor for any imperfections or areas that may need touch-ups.

Touch-Ups: Any necessary touch-ups are made to ensure a smooth, uniform appearance.

Top Coat Application

Mixing the Top Coat: A clear or tinted top coat is prepared, providing additional protection and a glossy finish.

Applying the Top Coat: The top coat is applied over the cured base coat, sealing the surface and adding durability.

Final Curing: The top coat is allowed to cure completely, which may take several hours to a few days, depending on the product.

Why Choose Solid Color Epoxy Flooring?

Versatility: Suitable for a variety of basement uses, from practical storage areas to stylish living spaces.

Professional Installation: Our expert team ensures a flawless application, maximizing the benefits of your new epoxy floor.

Final Inspection and Clean-Up

Final Quality Check: A thorough inspection is conducted to ensure the floor meets our high standards of quality and appearance.

Clean-Up: The work area is cleaned, and any protective coverings are removed.

Post-Installation Care and Maintenance Instructions:

• Care Guidelines: We provide you with detailed instructions on how to care for and maintain your new epoxy floor to keep it looking its best.

• First Use: Guidelines on how long to wait before using the floor to ensure it is fully cured and ready for foot traffic or furniture placement.

Scroll down to see some our completed projects

Benefits:

✅ Durability and Longevity:

Epoxy floors are known for their toughness and resistance to wear and tear. They can withstand heavy foot traffic, making them ideal for a basement that may be used frequently.

Epoxy flooring is highly resistant to impacts and abrasions, ensuring it remains intact and looking good even if heavy items are dropped.

✅ Aesthetics and Customization:

A solid color epoxy floor provides a sleek, seamless, and contemporary finish that can enhance the overall appearance of the basement.

Available in a wide range of colors, you can choose a hue that matches your personal style or complements the existing decor of your home.

✅ Maintenance & Hygiene:

The smooth, non-porous surface of an epoxy floor makes it incredibly easy to clean. Spills can be wiped away effortlessly, and regular maintenance requires minimal effort.

Epoxy floors resist stains from liquids such as water, oil, and chemicals, ensuring the floor maintains its pristine look.

✅ Performance and Safety:

Epoxy flooring creates a moisture-resistant barrier, which is especially beneficial in basements prone to dampness or minor flooding.

Epoxy coatings can be customized with slip-resistant additives to enhance safety, reducing the risk of slips and falls.

✅ Installation and Usability:

Epoxy flooring can be installed relatively quickly, minimizing disruption to your home.

The seamless nature of epoxy flooring eliminates cracks and crevices where dirt and bacteria can accumulate, promoting a cleaner environment.

✅ Cost-Effectiveness:

Although the initial cost may be higher than some other flooring options, the durability and low maintenance requirements of epoxy floors can lead to long-term cost savings.

The improved appearance and functionality of a basement with epoxy flooring can increase the overall value of your home.

✅ Environmental Benefits:

Some epoxy products are low in volatile organic compounds (VOCs), contributing to better indoor air quality and a healthier living environment.

Application Process:

Initial Consultation and Assessment

Site Visit: We begin with a visit to your basement to assess the condition of the floor and discuss your colour and design preferences.

Preparation Plan: We’ll develop a tailored preparation and installation plan based on the specific requirements of your space.

Surface Preparation

Cleaning: The existing floor is thoroughly cleaned to remove any dirt, grease, or debris. This ensures optimal adhesion of the epoxy.

Repairs: Any cracks, holes, or imperfections in the concrete are repaired using an appropriate filler or patching material.

Grinding/Shot Blasting: The surface is mechanically ground or shot blasted to create a rough texture, promoting better bonding of the epoxy coating.

Vacuuming: The floor is vacuumed to remove dust and particles generated during grinding or shot blasting.

Primer Application

Primer Coat: A primer coat of epoxy is applied to the prepared surface. This penetrates the concrete, creating a strong foundation for the subsequent layers.

Curing Time: The primer is allowed to cure for the recommended period, ensuring it bonds effectively to the substrate.

Base Coat Application

Mixing the Epoxy: The epoxy resin and hardener are mixed according to the manufacturer’s specifications to achieve the desired consistency.

Applying the Base Coat: The mixed epoxy is applied evenly across the floor using rollers or squeegees. This base coat serves as the primary color layer.

Curing Time: The base coat is left to cure, typically overnight, depending on the product and environmental conditions.

Inspection and Touch-Ups

Quality Check: Once the base coat is cured, we inspect the floor for any imperfections or areas that may need touch-ups.

Touch-Ups: Any necessary touch-ups are made to ensure a smooth, uniform appearance.

Top Coat Application

Mixing the Top Coat: A clear or tinted top coat is prepared, providing additional protection and a glossy finish.

Applying the Top Coat: The top coat is applied over the cured base coat, sealing the surface and adding durability.

Final Curing: The top coat is allowed to cure completely, which may take several hours to a few days, depending on the product.

Why Choose Solid Color Epoxy Flooring?

Versatility: Suitable for a variety of basement uses, from practical storage areas to stylish living spaces.

Professional Installation: Our expert team ensures a flawless application, maximizing the benefits of your new epoxy floor.

Final Inspection and Clean-Up

Final Quality Check: A thorough inspection is conducted to ensure the floor meets our high standards of quality and appearance.

Clean-Up: The work area is cleaned, and any protective coverings are removed.

Post-Installation Care and Maintenance Instructions:

• Care Guidelines: We provide you with detailed instructions on how to care for and maintain your new epoxy floor to keep it looking its best.

• First Use: Guidelines on how long to wait before using the floor to ensure it is fully cured and ready for foot traffic or furniture placement.

Scroll down to see some our completed projects

Benefits:

✅ Durability and Longevity:

Epoxy floors are known for their toughness and resistance to wear and tear. They can withstand heavy foot traffic, making them ideal for a basement that may be used frequently.

Epoxy flooring is highly resistant to impacts and abrasions, ensuring it remains intact and looking good even if heavy items are dropped.

✅ Aesthetics and Customization:

A solid color epoxy floor provides a sleek, seamless, and contemporary finish that can enhance the overall appearance of the basement.

Available in a wide range of colors, you can choose a hue that matches your personal style or complements the existing decor of your home.

✅ Maintenance & Hygiene:

The smooth, non-porous surface of an epoxy floor makes it incredibly easy to clean. Spills can be wiped away effortlessly, and regular maintenance requires minimal effort.

Epoxy floors resist stains from liquids such as water, oil, and chemicals, ensuring the floor maintains its pristine look.

✅ Performance and Safety:

Epoxy flooring creates a moisture-resistant barrier, which is especially beneficial in basements prone to dampness or minor flooding.

Epoxy coatings can be customized with slip-resistant additives to enhance safety, reducing the risk of slips and falls.

✅ Installation and Usability:

Epoxy flooring can be installed relatively quickly, minimizing disruption to your home.

The seamless nature of epoxy flooring eliminates cracks and crevices where dirt and bacteria can accumulate, promoting a cleaner environment.

✅ Cost-Effectiveness:

Although the initial cost may be higher than some other flooring options, the durability and low maintenance requirements of epoxy floors can lead to long-term cost savings.

The improved appearance and functionality of a basement with epoxy flooring can increase the overall value of your home.

✅ Environmental Benefits:

Some epoxy products are low in volatile organic compounds (VOCs), contributing to better indoor air quality and a healthier living environment.

Application Process:

Initial Consultation and Assessment

Site Visit: We begin with a visit to your basement to assess the condition of the floor and discuss your colour and design preferences.

Preparation Plan: We’ll develop a tailored preparation and installation plan based on the specific requirements of your space.

Surface Preparation

Cleaning: The existing floor is thoroughly cleaned to remove any dirt, grease, or debris. This ensures optimal adhesion of the epoxy.

Repairs: Any cracks, holes, or imperfections in the concrete are repaired using an appropriate filler or patching material.

Grinding/Shot Blasting: The surface is mechanically ground or shot blasted to create a rough texture, promoting better bonding of the epoxy coating.

Vacuuming: The floor is vacuumed to remove dust and particles generated during grinding or shot blasting.

Primer Application

Primer Coat: A primer coat of epoxy is applied to the prepared surface. This penetrates the concrete, creating a strong foundation for the subsequent layers.

Curing Time: The primer is allowed to cure for the recommended period, ensuring it bonds effectively to the substrate.

Base Coat Application

Mixing the Epoxy: The epoxy resin and hardener are mixed according to the manufacturer’s specifications to achieve the desired consistency.

Applying the Base Coat: The mixed epoxy is applied evenly across the floor using rollers or squeegees. This base coat serves as the primary color layer.

Curing Time: The base coat is left to cure, typically overnight, depending on the product and environmental conditions.

Inspection and Touch-Ups

Quality Check: Once the base coat is cured, we inspect the floor for any imperfections or areas that may need touch-ups.

Touch-Ups: Any necessary touch-ups are made to ensure a smooth, uniform appearance.

Top Coat Application

Mixing the Top Coat: A clear or tinted top coat is prepared, providing additional protection and a glossy finish.

Applying the Top Coat: The top coat is applied over the cured base coat, sealing the surface and adding durability.

Final Curing: The top coat is allowed to cure completely, which may take several hours to a few days, depending on the product.

Why Choose Solid Color Epoxy Flooring?

Versatility: Suitable for a variety of basement uses, from practical storage areas to stylish living spaces.

Professional Installation: Our expert team ensures a flawless application, maximizing the benefits of your new epoxy floor.

Final Inspection and Clean-Up

Final Quality Check: A thorough inspection is conducted to ensure the floor meets our high standards of quality and appearance.

Clean-Up: The work area is cleaned, and any protective coverings are removed.

Post-Installation Care and Maintenance Instructions:

• Care Guidelines: We provide you with detailed instructions on how to care for and maintain your new epoxy floor to keep it looking its best.

• First Use: Guidelines on how long to wait before using the floor to ensure it is fully cured and ready for foot traffic or furniture placement.

Scroll down to see some our completed projects

Photo Gallery

Our Gallery

Discover our past projects.

Photo Gallery

Our Gallery

Discover our past projects.

Photo Gallery

Our Gallery

Discover our past projects.

Frequently Asked Questions

Your Questions Answered!

Discover more about our services and policies with our Frequently Asked Questions section.

Frequently Asked Questions

Your Questions Answered!

Discover more about our services and policies with our Frequently Asked Questions section.

Frequently Asked Questions

Your Questions Answered!

Discover more about our services and policies with our Frequently Asked Questions section.

Question

Answer

What is the total cost estimate and what does it include?

Question

Answer

What are your payment terms?

Question

Answer

Does epoxy crack in the winter?

Question

Answer

How long does an epoxy job take?

Question

Answer

Is Just Perfect Resin liscensed and insured?

Question

Answer

Do you offer any warranties or guarantees on your work?

Question

Answer

Does epoxy resist against stains?

Question

Answer

What can epoxy be applied too?

Question

Answer

What is the total cost estimate and what does it include?

Question

Answer

What are your payment terms?

Question

Answer

Does epoxy crack in the winter?

Question

Answer

How long does an epoxy job take?

Question

Answer

Is Just Perfect Resin liscensed and insured?

Question

Answer

Do you offer any warranties or guarantees on your work?

Question

Answer

Does epoxy resist against stains?

Question

Answer

What can epoxy be applied too?

What is the total cost estimate and what does it include?

What are your payment terms?

Does epoxy crack in the winter?

How long does an epoxy job take?

Is Just Perfect Resin liscensed and insured?

Do you offer any warranties or guarantees on your work?

Question

Answer

Does epoxy resist against stains?

Question

Answer